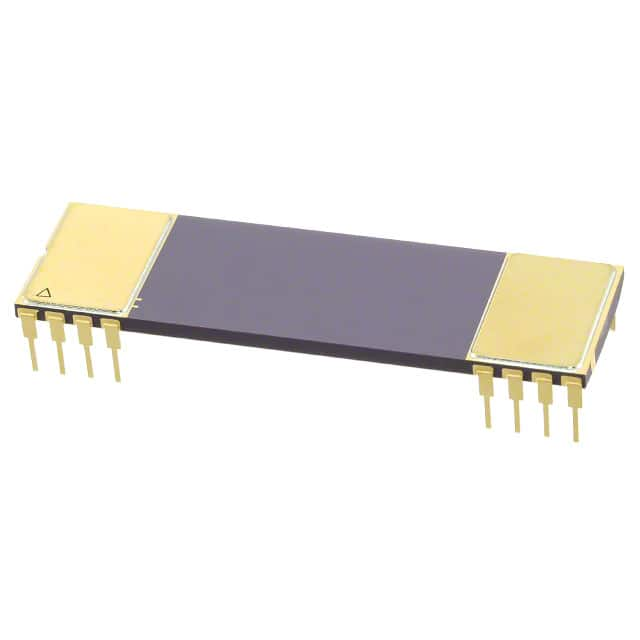

ISO106 Texas Instruments IC OPAMP ISOLATION 70KHZ 16CDIP

Integraallülitused (IC-d)

Tootja number:

ISO106

Tootja:

Tootekategooria:

Kirjeldus:

IC OPAMP ISOLATION 70KHZ 16CDIP

RoHs olek:

Andmetabelid:

-3 db ribalaius :

70kHz

Osa olek :

Obsolete

Paigaldustüüp :

Through Hole

Pakend/ümbris :

40-CDIP (0.600", 15.24mm), 16 Leads

Pakendamine :

Tube

Pinge – sisendi nihe :

25mV

Pinge – toide, üks/kaks (±) :

±10 V ~ 20 V

Pöördekiirus :

0.5 V/µs

Praegune – pakkumine :

25mA

Praegune – sisendi kallutatus :

-

Praegune – väljund / kanal :

5mA

Ribalaiuse suurendamise toode :

-

seeria :

-

Tarnija seadmepakett :

16-CDIP

Töötemperatuur :

-25°C ~ 85°C

Väljundi tüüp :

-

Võimendi tüüp :

Isolation

Vooluahelate arv :

1

Laos

19,980

Ühiku hind:

Võtke meiega ühendust Pakkumine

ISO106 Konkurentsivõimelised hinnad

ChipIcil on ainulaadne tarneallikas. Pakume oma klientidele ISO106 konkurentsivõimelise hinnaga. Saate nautida meie parimat teenust, ostes ChipIc ISO106. Parima hinna saamiseks saidil ISO106 võtke meiega ühendust.

Hinnapakkumise saamiseks klõpsake

ISO106 Iseärasused

ISO106 is produced by Texas Instruments, belongs to Lineaarne – võimendid – mõõteriistad, OP-võimendid, puhvervõimendid.

ISO106 Toote üksikasjad

:

ISO106 – Lineaarne – võimendid – mõõteriistad, OP-võimendid, puhvervõimendid disainitud puhvervõimendid ja toodetud Texas Instruments.

ISO106, mida pakub Texas Instruments, saab osta CHIPMLCC-st.

Siit leiate erinevaid juhtivate tootjate elektroonilisi osi rahu.

CHIPMLCC ISO106 on range kvaliteedikontrolliga ja nõuetele vastav kõike nõuetele.

CHIPMLCC-s näidatud fondi staatus on ainult viitamiseks.

Kui te ei leia otsitavat osa, võtke meiega ühendust lisateavet, näiteks varude arvu andmetabelis ISO106 (PDF), hind ISO106, Pinout ISO106, manuaal ISO106 Ja ISO106 asenduslahendus.

ISO106, mida pakub Texas Instruments, saab osta CHIPMLCC-st.

Siit leiate erinevaid juhtivate tootjate elektroonilisi osi rahu.

CHIPMLCC ISO106 on range kvaliteedikontrolliga ja nõuetele vastav kõike nõuetele.

CHIPMLCC-s näidatud fondi staatus on ainult viitamiseks.

Kui te ei leia otsitavat osa, võtke meiega ühendust lisateavet, näiteks varude arvu andmetabelis ISO106 (PDF), hind ISO106, Pinout ISO106, manuaal ISO106 Ja ISO106 asenduslahendus.

ISO106 FAQ

:

1. What is the purpose of ISO106 in semiconductor manufacturing?

ISO106 specifies the requirements for the characterization of ultra-pure water used in the semiconductor industry, ensuring that the water meets stringent quality standards for use in critical processes.

2. What are the key parameters monitored under ISO106 for ultra-pure water?

ISO106 focuses on monitoring parameters such as resistivity, total organic carbon (TOC), particles, bacteria, and endotoxins to ensure the water's purity and suitability for semiconductor fabrication.

3. How is resistivity measured in accordance with ISO106?

Resistivity is typically measured using a high-precision instrument known as a resistivity meter, which assesses the water's electrical resistance and provides a direct indication of its purity.

4. What methods are employed for the detection and control of TOC in ultra-pure water as per ISO106?

ISO106 recommends the use of advanced analytical techniques such as UV oxidation and conductivity measurements to accurately detect and control TOC levels within specified limits.

5. How are particle counts determined in compliance with ISO106 standards?

Particle counts are commonly assessed using laser-based particle counters, which can accurately quantify and classify particles present in ultra-pure water down to specified size ranges.

6. What measures are recommended by ISO106 to prevent bacterial contamination in ultra-pure water systems?

ISO106 outlines strict protocols for system design, maintenance, and sanitation, including the use of effective filtration, disinfection, and periodic monitoring to minimize the risk of bacterial contamination.

7. Can you explain the significance of endotoxin testing in relation to ISO106 compliance?

Endotoxin testing is crucial for verifying the absence of bacterial endotoxins in ultra-pure water, as their presence can have detrimental effects on semiconductor manufacturing processes and product quality.

8. How does ISO106 address the issue of trace metal contamination in ultra-pure water?

ISO106 provides guidelines for controlling trace metal contamination through the use of appropriate materials, equipment, and monitoring procedures to maintain ultra-low levels of metals in the water.

9. What role does ISO106 play in ensuring the reliability and consistency of ultra-pure water for semiconductor applications?

ISO106 serves as a benchmark for establishing and maintaining the quality of ultra-pure water, thereby supporting the consistent performance and reliability of semiconductor manufacturing processes.

10. How can organizations effectively demonstrate compliance with ISO106 requirements for ultra-pure water?

Organizations can demonstrate compliance by implementing robust quality management systems, conducting regular audits, and maintaining comprehensive documentation of all activities related to ISO106 conformance.

ISO106 specifies the requirements for the characterization of ultra-pure water used in the semiconductor industry, ensuring that the water meets stringent quality standards for use in critical processes.

2. What are the key parameters monitored under ISO106 for ultra-pure water?

ISO106 focuses on monitoring parameters such as resistivity, total organic carbon (TOC), particles, bacteria, and endotoxins to ensure the water's purity and suitability for semiconductor fabrication.

3. How is resistivity measured in accordance with ISO106?

Resistivity is typically measured using a high-precision instrument known as a resistivity meter, which assesses the water's electrical resistance and provides a direct indication of its purity.

4. What methods are employed for the detection and control of TOC in ultra-pure water as per ISO106?

ISO106 recommends the use of advanced analytical techniques such as UV oxidation and conductivity measurements to accurately detect and control TOC levels within specified limits.

5. How are particle counts determined in compliance with ISO106 standards?

Particle counts are commonly assessed using laser-based particle counters, which can accurately quantify and classify particles present in ultra-pure water down to specified size ranges.

6. What measures are recommended by ISO106 to prevent bacterial contamination in ultra-pure water systems?

ISO106 outlines strict protocols for system design, maintenance, and sanitation, including the use of effective filtration, disinfection, and periodic monitoring to minimize the risk of bacterial contamination.

7. Can you explain the significance of endotoxin testing in relation to ISO106 compliance?

Endotoxin testing is crucial for verifying the absence of bacterial endotoxins in ultra-pure water, as their presence can have detrimental effects on semiconductor manufacturing processes and product quality.

8. How does ISO106 address the issue of trace metal contamination in ultra-pure water?

ISO106 provides guidelines for controlling trace metal contamination through the use of appropriate materials, equipment, and monitoring procedures to maintain ultra-low levels of metals in the water.

9. What role does ISO106 play in ensuring the reliability and consistency of ultra-pure water for semiconductor applications?

ISO106 serves as a benchmark for establishing and maintaining the quality of ultra-pure water, thereby supporting the consistent performance and reliability of semiconductor manufacturing processes.

10. How can organizations effectively demonstrate compliance with ISO106 requirements for ultra-pure water?

Organizations can demonstrate compliance by implementing robust quality management systems, conducting regular audits, and maintaining comprehensive documentation of all activities related to ISO106 conformance.

ISO106 Seotud märksõnad

:

ISO106 Hind

ISO106 Maalimine

ISO106 Tihvtide pinge

Pakkumised: Kiire hinnapakkumise kontroll

Minimaalne tellimus: 1

Sisaldab "ISO1" seeria tooteid